Many years have passed since the beginnings of LED lights in the vehicle sector. The technology has evolved and the products are now more versatile and reliable than ever before. Nevertheless, one problem remains: the challenges after installation, especially with LED tail, stop and direction indicator lights. The lower load of LED lights often leads to perceived faults in the lighting system, which are detected by the on-board electronics. Why? The new load does not meet the expectations of the monitoring systems.

The introduction of ISO 13207-1

A solution has been available since 2012: ISO standard 13207-1. This standard defines the parameters for direction indicator failure monitoring for LED lights. According to ECE Regulation 48, the direction indicator failure check is the only legally required monitoring system for lights on vehicles and trailers. Despite this, only a few manufacturers, apart from us, consistently implement this standard.

Challenges in the monitoring of LED lights

Many automotive and commercial vehicle manufacturers also monitor numerous other light functions. This monitoring varies from manufacturer to manufacturer and ranges from checking the brake light to checking all light functions, including reversing lights and license plate lights. However, there is no uniform standard for this – apart from the aforementioned ISO 13207-1, which is not mandatory.

Hot and cold monitoring: two methods for monitoring

There are two main methods for monitoring light functions: the „warm query“ and the „cold query“. With the warm query, the operating current of the luminaire is checked when it is switched on. With the cold test, on the other hand, a small test current flows when the luminaire is switched off. In some cases, both methods are combined.

However, these methods can lead to problems if vehicles or trailers are fitted with LED lights. Due to the significantly lower operating currents of LED lights, various malfunctions can occur. Examples of this are a slight glow of the LED lights due to the test current during the cold check, error messages in the vehicle or incorrect detection of a coupled trailer by the towing vehicle. This can even lead to the HVF device (power protection anchorage) not functioning correctly.

Solutions for adapting to LED technology

The safest way to avoid these problems is to reprogram the on-board computer to the new performance values of the LED lights. However, this is not possible in many vehicles. An alternative solution is to install high- or low-impedance resistors in parallel with the LED light for all light functions, depending on the light output. However, only systems that enable reliable detection of failure or falling below the required light values in accordance with ECE may be used for the direction indicator lights.

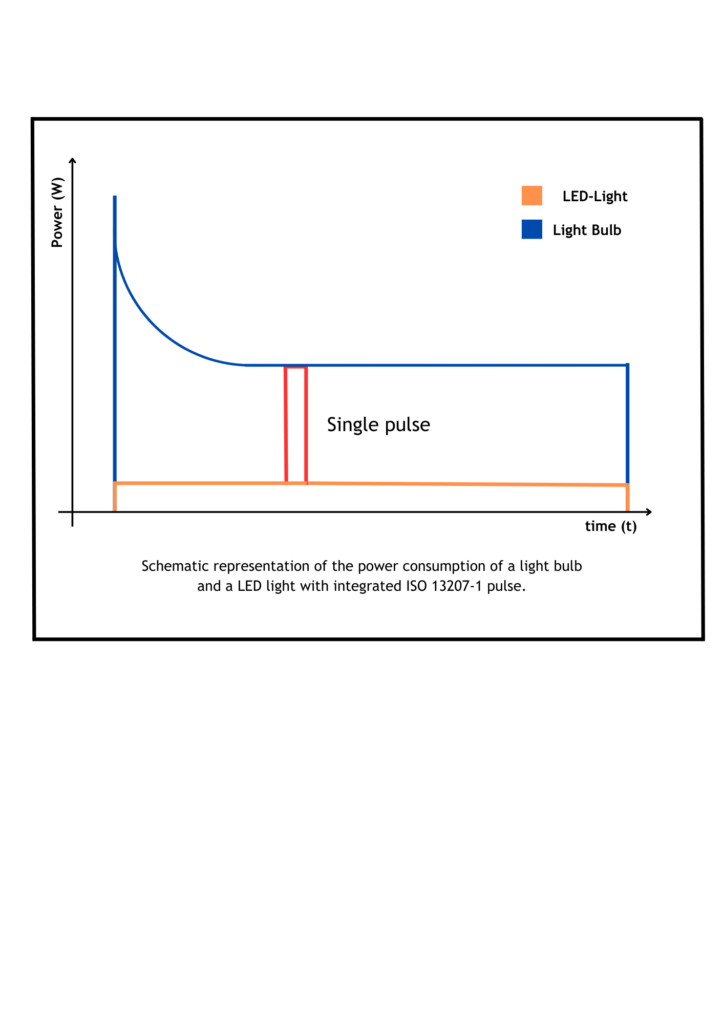

The pulse according to ISO 13207-1

The ISO 13207-1 standard offers an innovative solution to the challenges posed by the use of LED lights in vehicles. This standard defines a clocked pulse that mimics the power consumption of an incandescent lamp so that LED lamps are correctly detected and do not cause any error messages. Most of our lights are equipped with this pulse, which significantly increases their reliability.

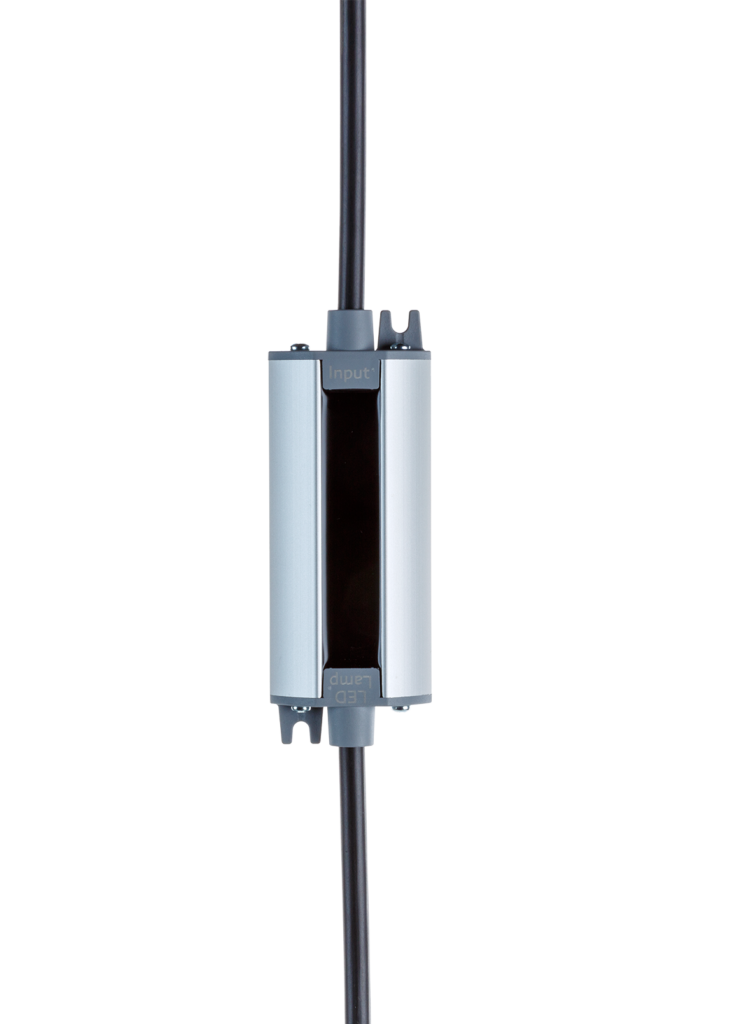

However, if luminaires without an integrated pulse have been installed, we offer an effective solution in the form of the PULSEmann module. The PULSEmann module is a control and load unit for LED vehicle lights that works in accordance with ISO 13207-1. It ensures reliable direction indicator failure detection and enables the operation of lights without incorrect failure detection. Simply integrated between the supply line and the light, it offers a seamless and safe solution.

Our innovations in the field of LED technology

We are proud to offer a wide range of vehicle lights in various forms. Our range extends from single-function lights to combination lights that combine several functions in one housing. Our combination lights, which combine brake light, tail light and direction indicator, are particularly popular. We also offer lights that combine rear fog light and reversing light or front direction indicator and front outline marker light.

Particular highlights are our new developments, which impress with their compact design and the possibility of customization. We have managed to integrate the pulse in accordance with ISO 13207-1 into almost all of our direction indicator lights, which further increases the reliability and safety of our products.

We also produce various electronic modules that ensure the approval-compliant operation of LED indicators. These modules ensure that the failure detection of the LED flashing lights works and prevent false failure messages. Our latest modules are ISO 13207-1 compliant and offer maximum reliability and safety.

We offer both integrated solutions and supplementary

electronic modules to meet the needs of our customers.

Conclusion

ISO 13207-1 is a decisive step towards standardized monitoring of LED direction indicator lights and offers a solution to the problems frequently encountered with modern LED lights in the vehicle sector. Our products and innovations follow this standard and thus offer not only legally compliant, but also reliable and flexible solutions for a wide range of applications. With our new, compact and adaptable LED lights, we are setting standards in vehicle lighting.