LED lamp development - All Services from Jedermann AG

Planning, construction, production and quality management – all of that is merged under our roof. Over the last couple of decades we have accumulated knowledge in all kinds of areas.

By the integration of several new departments we enabled ourselves to control the complete production process of our products in our own factory. Since we only use third-party services to a very limited extent, we are flexible and independent. You get all services for LED lamp development from one place.

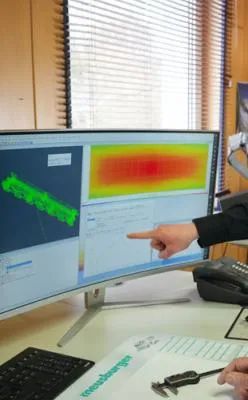

Product development for LED lamps

We develop eye-catchers with modern technology

The combination of long-lasting experience, modern development software and our own laboratory enables us to develop innovative vehicle lights in a short time.

Regardless of whether we use free-from optics or light guide systems – all of our new developments are equipped with state-of-the-art LED technology. With the help of self-manufactured prototypes and simulations, we can evaluate our developments from all angles even before the start of the series production.

The injection moulds as well as other tools that are required for the production of our products are all developed and manufactured in our factory.

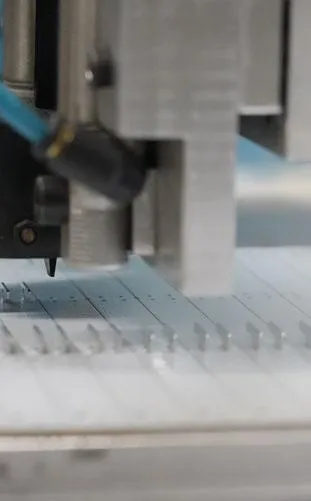

Mould construction

Here you get in contact with state-of-the-art technology that has substituted conventional processing machines. CNC vertical eroding and wire eroding machines as well as CNC high-speed milling are all part of the day-to-day work of our tool mechanics.

The paperless mould construction became reality for us a long time ago. At several CAM workstations the construction data from the development department is processed by our highly-qualified tool mechanics into executable programs for our machines.

Because of that, our new developments and adjustments to already existing products can be implemented quickly.

Injection moulding

We have 15 injection moulding machines with modern extraction systems at our disposal for the production of the polymer parts. The mould closure force of our machines ranges from 120 kN to 1,600 kN.

More than 50 years of experience in the production of polymer parts are the basis for the production of even the most complex parts out of a variety of different materials. Our certified quality management system in combination with the automated production data acquisition constantly ensures the quality of our production.

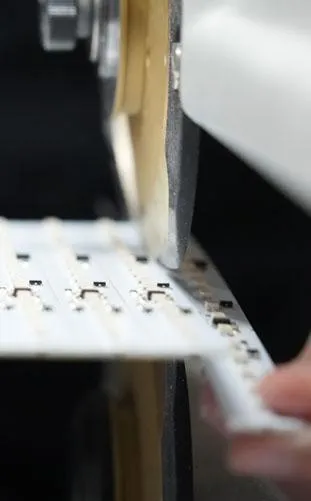

Electronics production

Our electronics solutions are the heart of our products

In our in-house electronics production we assemble, solder and program printed circuit boards. Afterwards, a comprehensive functionality test of the printed circuit boards is conducted. By means of our own electronics assembly line we can shorten the production time and carry out specific customer requests.

Vacuum metallization

To create the mirror surfaces, we use our modern PVD facility. In this facility high vacuum is created. Afterwards, the polymer parts are vaporized with aluminum. We are especially proud on this in-house solution since only a few companies master this procedure.

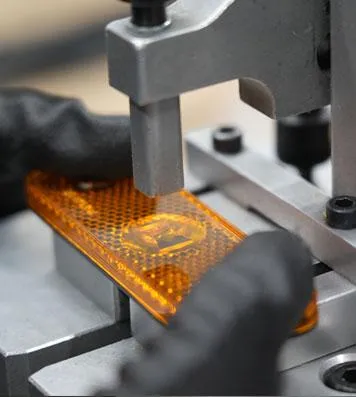

laser processing

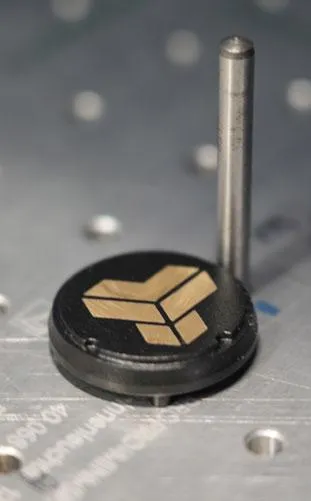

Laser stations put the finishing touches on our products and are also part of the LED lamp development service

Laser processing represents our newest in-house solution. With the help of laser stations, it is possible to label different kinds of surfaces after their production.

Our CO2 laser enables us to engrave polymer and aluminum parts. This laser is especially useful for adding homologation related information onto the outer surface of our products.

In addition to that, our YAG laser creates the opportunity for us to create a color change of the polymer material. Thereby, we can create high contrast labels on our products. This is particularly interesting for adding customer-specific logos and writings.

Product assembly

We can assemble quickly despite a high degree of variant

diversity

Our largest department in terms of employee count is the product assembly. Over the years, several new assembly methods have been introduced. Besides the conventional assembly, the department includes other procedures such as ultrasonic welding, different crimping methods and waterproof potting.

The large variant diversity and our own demand for fast order processing require a high degree of flexibility in the assembly of our products. We create the foundation for efficient processes with the help of our well-coordinated, highly qualified team, high stock keeping and a modern enterprise resource management system.

Quality management

Our way of working guarantees the highest quality standards

Our goal is to constantly offer our customers the highest quality and abide by the rules set out by the European regulatory authorities. Our ISO9001:2015 certificate serves as proof for the quality of our production.

We have our own laboratory where we can perform photometric measurements, specifically regarding light intensity and light color. In addition to that, we also constantly monitor water tightness, the overall function and many more parameters of our products.

Due to the high amount of manual labor that is combined with automated monitoring systems, we can control the quality of our products at all times. By doing so, we abide by our own quality standard and achieve a minimal reject rate.

“Our company stands for the highest quality in the development and production of light technology.”

By the way, the first electrically driven construction site lamp was developed and produced by us.

Since that time, we have achieved an enormous in-house depth of production which ranges from the first idea to the finished lamp and includes all necessary constructions, simulations, production and assembly steps as well as quality controls.

Our LED lamp development services

- Product development of LED Lamps from scratch

- Modern mould construction – we offer all services around LED lamps

- Injection moulding with our own machines

- Electronics production of the LED lamps

- Vacuum metallization for perfect shine

- In-house laser processing puts the finishing touches on our polymer parts

- In-house product assembly guarentees fast processing and high quality

- Quality Management rounds off our LED lamp development